You are currently viewing the James Walker Australia & New Zealand website. Click here to view the Global website.

You are currently viewing the James Walker Australia & New Zealand website. Click here to view the Global website.

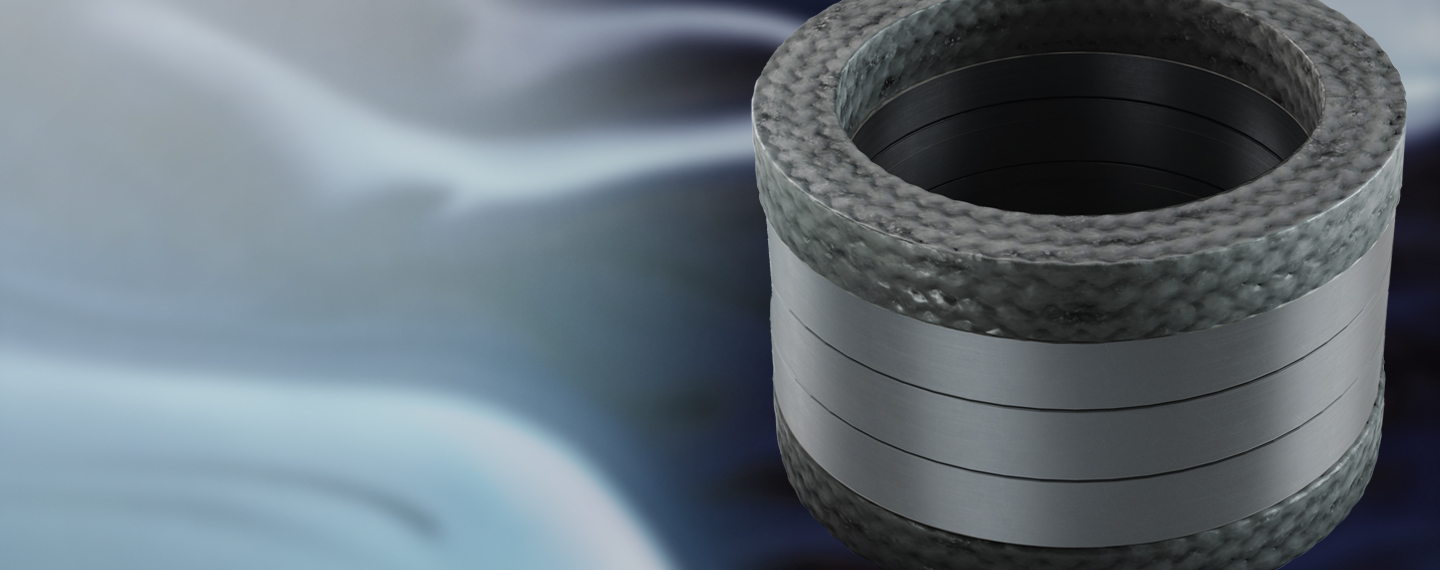

An ultra‑low emission combination valve stem packing set based on class‑leading graphite products and additive technology

Supagraf 100FXI CS is the first packing qualified to API 622, Annex C (HT), 2022 and ensures ultra-low emissions performance even at high temperatures combined with zero corrosion and virtually zero friction.

End rings: Braided high purity packing made from expanded graphite inconel wire mesh jacketed yarn for high strength and extrusion resistance with excellent sealability. The packing is impregnated with a high temperature resistant, proprietary emulsion to ensure extremely low friction. These rings conform to Shell material specification MESC SPE 85/204.

Intermediate rings: Special moulded rings of high purity graphite foil, that offer low friction and excellent heat transfer characteristics, plus high efficiency sealing. These rings conform to Shell material specification MESC SPE 85/203.

• First packing qualified to API 622, Annex C (HT) 2022 requirement - Yarmouth Research and Technology, USA.

• Unrivalled low emissions: 10 to 12 ppm maximum leakage across the size over 1510 cycles with no adjustments.

• Certified Fire Safe to API 607 8th edition with zero leakage during and after fire.

• TA Luft 2021 validated.

• Zero corrosion in both ambient and high temperature operation under API 622 testing.

• Ultra-low friction even at high endurance. (Tested friction factor: 0.1)

• Tested in supercritical phase of CO2 following ISO 15848 upto CO3 endurance class to tightness class 'A' with no stem seal adjustment required.

• All materials are PFAS surfactant free.

• Extremely low oxidation loss.