You are currently viewing the James Walker Global website.

You are currently viewing the James Walker Global website.

Due to the unreliable performance of both mechanical seals (catastrophic failure) and compression packing constant product leakage) when fitted to this application the customer was experiencing heavy product loss which was not only costly but created a safety issue.

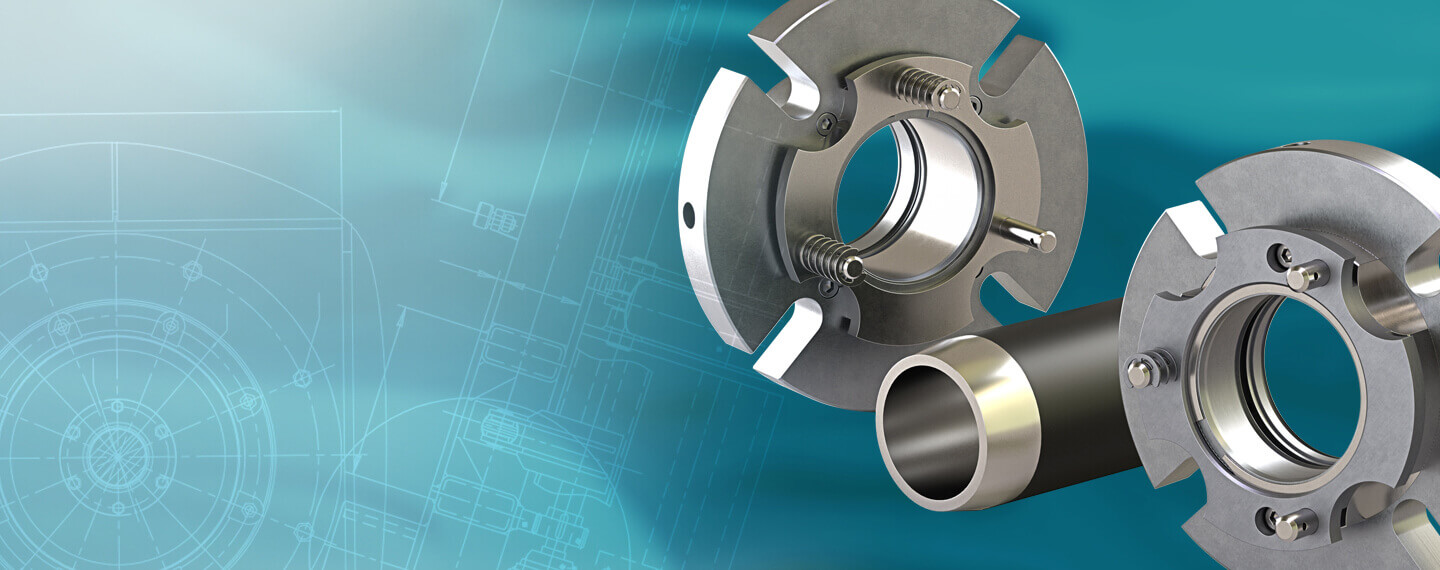

Gould’s 3175S centrifugal pump at a paper mill in America.

Compression packing

To overcome the existing issues, a KlickFix cartridge fitted using the customer shaft sleeve with clean water flush was applied. The cartridge uses a sequentially deployable sealing lip system with six lips to eliminate the risk of catastrophic failure. The cartridge uses a sequentially deployable sealing lip system with six lips to eliminate the risk of catastrophic failure. Utilising the stored lips in the cartridge is a quick and simple process with minimal downtime.

The KlickFix cartridge was installed and ran trouble free for ten months before clean flush water leakage was observed from the outboard side (not product), at which point the second sealing lip was then successfully deployed. Since the installation of KlickFix, the customer has massively reduced the health and safety risks associated with the previous sealing solutions.

Want to discuss your project, engineering or materials challenge expert to expert? Simply provide us with your contact details and a little information about the application you are working on, and one of our experts will contact you as soon as possible.