You are currently viewing the James Walker Global website.

You are currently viewing the James Walker Global website.

Working at the forefront of a new industry to assist development of a safe, sustainable energy source for all our futures.

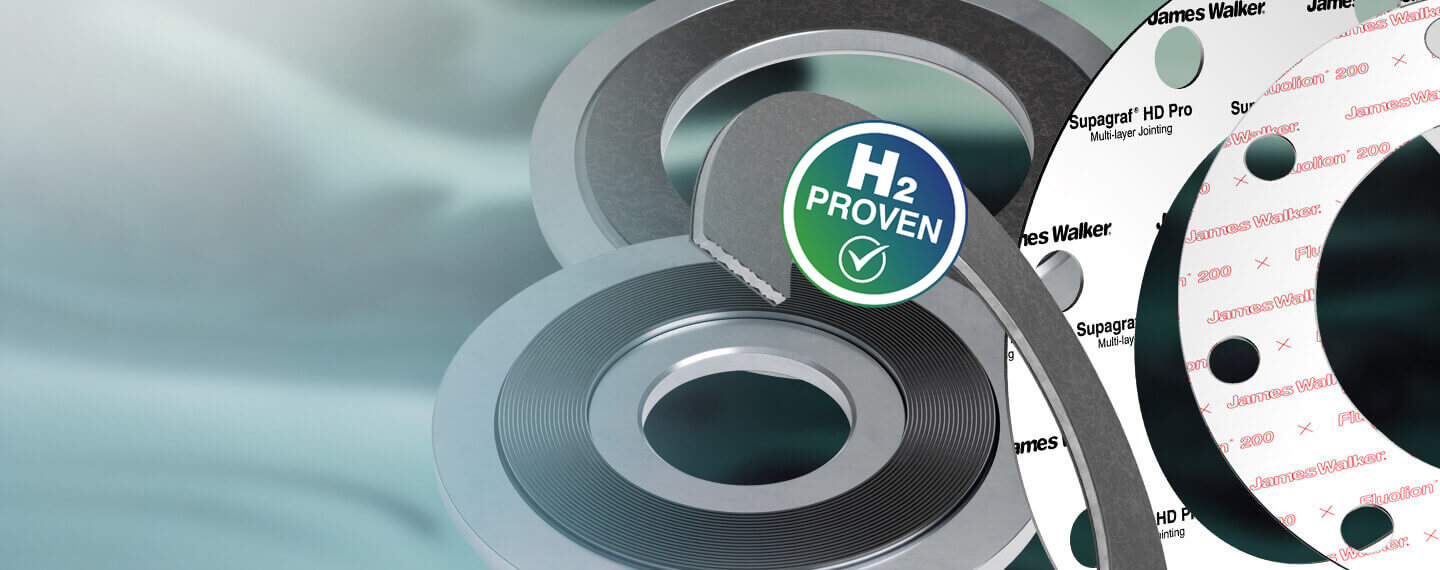

A gasket is often the most practical and cost effective way to seal a bolted flange joint, however the problem for designers and maintenance engineers, with challenging media such as hydrogen at up to 100% concentration or mixed with H2S, CO2, or natural gas, is to select the correct type to ensure process integrity and safe operation. This is where our experience lies.

Our work at the forefront of sealing technology gives us a clear understanding of the roles that different types of gaskets, their design and latest material technology play in flange sealing, particularly in hydrogen applications where specific material grades, exceptional tightness, fire safety, electrical conductivity or anti-static properties are critical.

Our hydrogen validated gaskets have been proven as bolted flange connection sealing solutions for hydrogen service up to 100% concentration with exceptional sealing performance (please contact James Walker for test reports, case histories or other supporting materials).

Our Centurion X, Chieftain X and Sentinel X, high performance CNAF gaskets are all also suitable for bolted flange connections in peripheral applications of hydrogen production using renewable energy, electrolysis process, distribution and storage, or methanol and e-fuels production.

Want to discuss your project, engineering or materials challenge expert to expert? Simply provide us with your contact details and a little information about the application you are working on, and one of our experts will contact you as soon as possible.