You are currently viewing the James Walker Global website.

You are currently viewing the James Walker Global website.

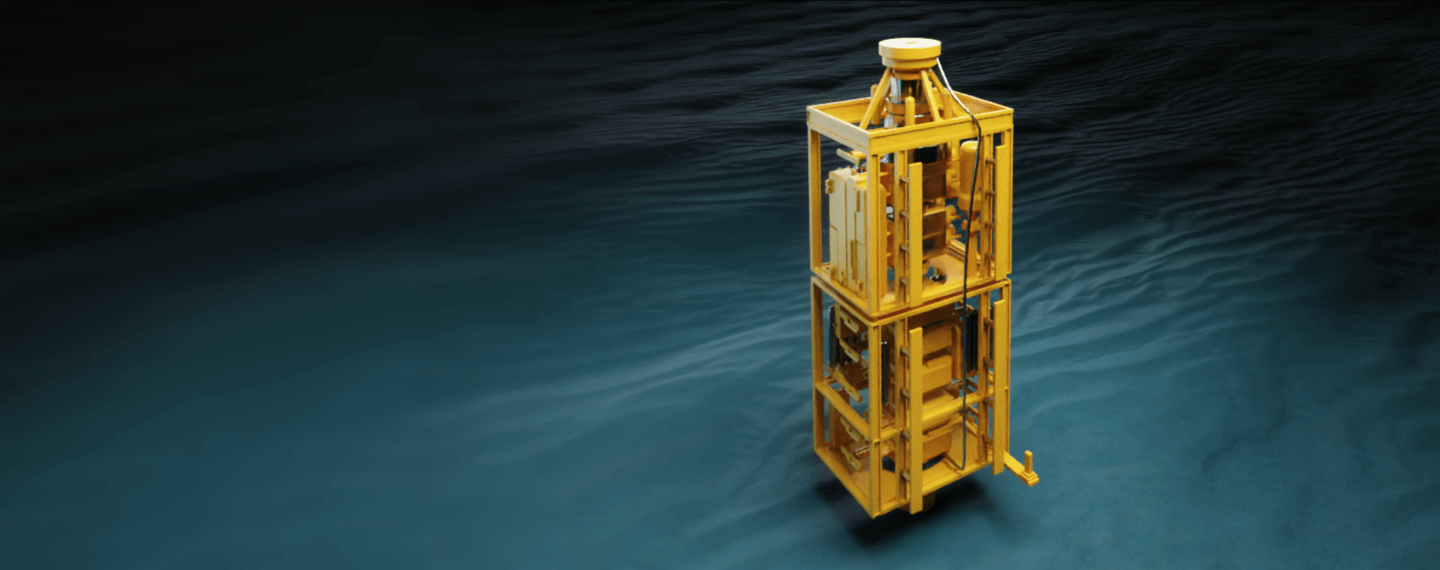

Sealing and critical components for subsea blowout prevention applications.

Tee-seals are used to solve problems commonly experienced by the manufacturers and users of oilfield equipment, including as subsea blowout preventers. This is a double acting seal and will effectively seal applications that are subjected to:

Tee-seals are capable of operating in a dynamic mode in applications involving high pressures and large extrusion gaps.

The excellent reputation of James Walker O-rings can be related to the materials from which they are manufactured. From the development of the first rapid gas decompression (RGD) resistant elastomers to the latest New Generation products, James Walker has led this area of material technology for more than 30 years.

Because our design engineers and material scientists understand the environments in which our products are required to perform, James Walker elastomers are not formulated purely for RGD resistance. We understand that factors such as temperature and media are often equally as important, so our materials are designed to offer excellent RGD resistance without compromising on performance in these other areas.

For over 40 years James Walker has led the development of elastomers for oil and gas applications. Today our extensive research on rapid gas decompression in carbon dioxide and screening of compounds in high levels of hydrogen sulphide provides the in-depth understanding driving the performance advances of our next generation compounds.

James Walker possesses one of the most advanced facilities in the world for rapid gas decompression testing. Capable of testing at pressures and decompression rates far greater than those required by international standards, this facility is just one of the reasons that James Walker continues to lead the way in the development of RGD resistant elastomers.

James Walker designs and manufactures components for use throughout the production stream including the following applications;

• Wellheads and trees

• Pipelines

• Tubing and casing seals

• Blow out prevention

• Pipeline intervention

• Subsea and process valves

Our metal end cap seals are hybrid metal/elastomer products with a high level of the extrusion resistance necessary for high pressure casing and tubing application. We have a long history of successfully designing these seals for ISO 10423 F.1.11 (pressure and thermal cycling) accreditation. Our metal end cap seals are often custom designed and manufactured to suit specific wellhead sealing environments. They are also available in a range of sections, sizes and materials.

As an OEM quality‑approved supplier for critical metallic components, our materials, products and processes are backed by full traceability, testing and quality programmes.

Our team has unrivalled expertise in the machining of complex, thin-walled, critical system seals in a range of high-specification alloys and titanium for use as primary barriers in high-pressure applications.

These profiles are achieved time and again, reliably and repeatedly to the required concentricity thanks to our in-depth understanding of the materials we are using and our machining processes.

Our manufacturing and machining expertise is backed by exceptional documentation and quality control. All of our materials are fully certified and sourced from customer approved, specialist suppliers and we offer total confidence throughout the manufacturing process with rigorous inspection programmes and documentation.

Bespoke quality plans are undertaken by our dedicated contract review and documentation team and can be supplied to API and NORSOK requirements, as well as integrated directly with online customer portals and completed to exacting customer specifications. A documented inspection before and after each manufacturing process ensures our customers have complete confidence in critical metallic seals supplied for industry's most demanding applications.

Want to discuss your project, engineering or materials challenge expert to expert? Simply provide us with your contact details and a little information about the application you are working on, and one of our experts will contact you as soon as possible.