You are currently viewing the James Walker Global website.

You are currently viewing the James Walker Global website.

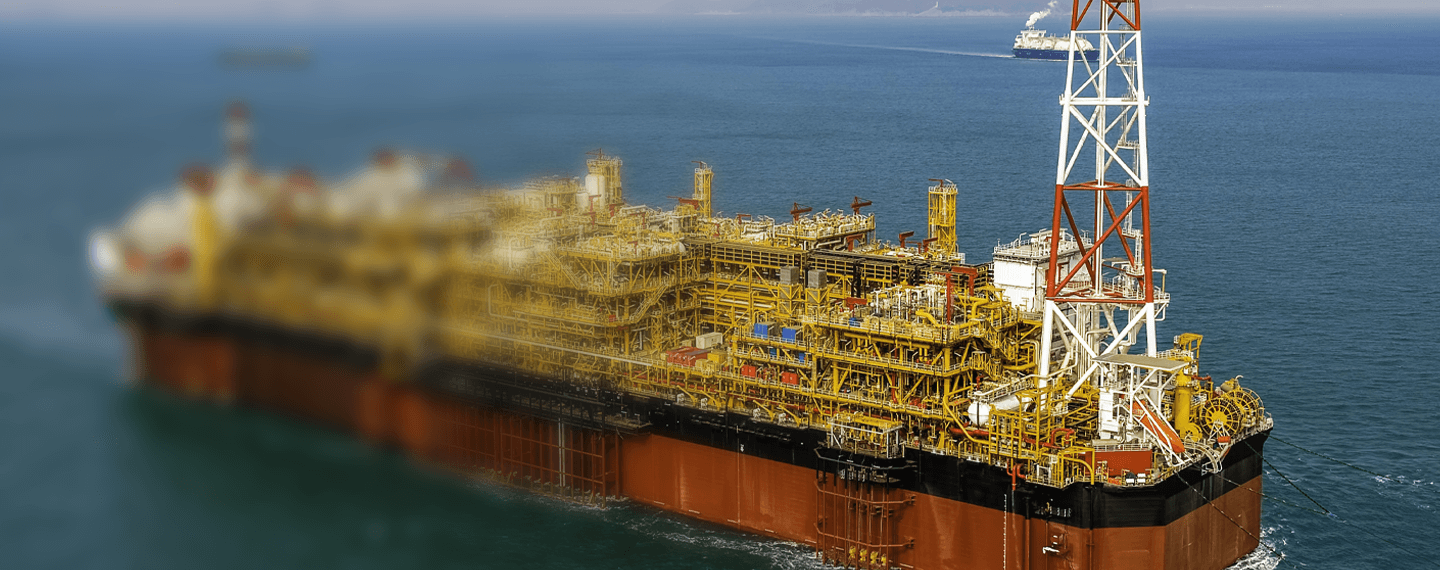

Sealing solutions and fugitive emissions control for pumps, pipelines and swivel connections on FPSO vessels.

James Walker offers a comprehensive range of Unilion precision-engineered spring-energised seals that can often perform three sealing duties - static, reciprocating and rotary and meet the following parameters:

Unilion is a long-life, low-friction seal with negligible leakage - even under physically demanding operating conditions involving highly corrosive fluid media or cryogenic temperatures and gases such as CO2 and hydrogen that preclude the use of more conventional elastomeric/polymeric seals on arduous duties in areas such as:

James Walker specialises in high-performance O-rings, manufactured in a variety of general and high performance elastomers to suit the vast majority of industrial and specialised applications.

At James Walker, we deliver bespoke O-rings that adhere to an extensive range of international, national and industry standards, with a focus on high-performance and high-pressure environments. We make use of a combination of general and high-performance elastomers, to create custom O-ring sealing solutions specifically engineered for the most demanding applications.

Our high performance fluoroelastomer (FKM), hydrogenated nitrile (HNBR) and aflas based (FEPM) elastomers are specified worldwide by customers who need top quality materials that are validated and proven to operate:

Our constant advances in materials and lubricants, product design and manufacturing techniques keep us at the forefront of compression packing technology. We therefore bring you one of the broadest compression packing ranges, which can be matched with the temperatures, pressures and speeds of your most modern fluid handling systems, and economical packings for your older plant.

Many of our compression packings will dramatically reduce your stockholding levels - as one carefully selected length-form product can often be used for many different valves, pumps and other fluid handling plant at your site.

James Walker has developed a range of graphite products specifically to combat fugitive VOC emissions from valves, including Supagraf 100FXI CS, Supagraf Premier, Supagraf Control, and Supagraf FE. These products are proven class-leaders in a series of third party fugitive emissions performance tests and are best available technique (BAT) products for reducing industry's fugitive emissions in line with the latest Industrial Emissions Directive.

We manufacture and supply complete ranges of metallic and semi-metallic joints, gaskets and sheet jointings to suit every fluid sealing application. We can produce precision-cut flat gaskets to any shape, size and quantity from any sheet material, including our own extensive ranges of jointings.

Our teams of experienced applications engineers and materials technologists are always available to help you select the correct gasket that matches your operational specifications, whatever the application.

A vast stock of flange gaskets is held ready for immediate despatch, and we can economically cut non-standard profiles of any complexity within minutes. If we do not have a gasket in our ranges to match your specific requirements, we have the capability to design a custom gasket, create a prototype and test a product that will.

Certificates of conformity to international or customer-specific standards can be supplied on request, with packaging and labelling available to individual specifications.

Traditional tightening practice measures tightening power or the effort applied. The belief is that there is a reliable correlation between the equipment tightening power and the residual bolt tension achieved - however, there is no reliable correlation. Factors including friction from interfaces such as head/nut bearing face and threads, as well as the inclusion of protective coatings for example, have a huge impact on exactly how much of the applied force translates into actual bolt tension. To guarantee that all bolts are installed to the correct design tension requires a different measuring principle - the principle at the heart of RotaBolt technology.

RotaBolt provides simple tactile and visual methods of checking tension control / bolt load without the need to use heavy tooling or delicate measuring equipment and minimises the risk to operatives requiring access to dangerous areas.

Complementing this product range, our engineering teams can offer training, installation, supervision, flange calculations and complete flange management services for critical flanges / hazardous areas of operation, providing customers with leak-free startup and operation with enhanced safety.

Follow this link for more information on load indicating bolting.

Want to discuss your project, engineering or materials challenge expert to expert? Simply provide us with your contact details and a little information about the application you are working on, and one of our experts will contact you as soon as possible.