You are currently viewing the James Walker Global website.

You are currently viewing the James Walker Global website.

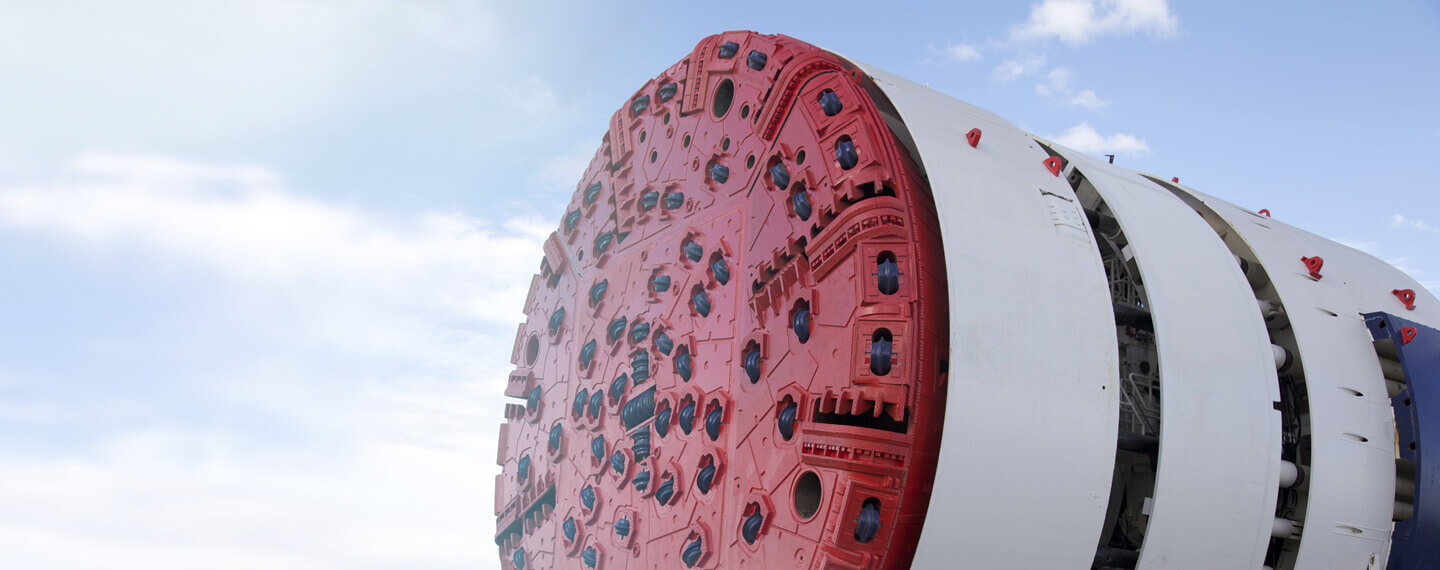

Our exceedingly robust Walkersele tunnel boring machine seals (TBMS) are designed to protect the cutting head bearings of tunnel boring machines.

Walkersele TBMS are well proven on many successful tunnelling projects, including the Channel Tunnel (7.8 m diameter) and the Airport Link Railway, Sydney (11 m diameter).

Exceedingly robust design of radial lip seal to work efficiently for the life of a tunnel boring project.

Manufactured from extremely tough, abrasion resistant elastomer-proofed fabric, and fitted with an O-ring to energise the lip.

Banks of Walkersele TBMS seals are installed behind the cutting head to protect the bearings from water, slurries, highly abrasive dust and grit.

Will operate at constant pressure differential of 300 kPa/3 bar (43.5 psi), with excursions to 400 kPa/4 bar. (58 psi). Maximum static pressure differential is 1 MPa/10 bar (145 psi). Sealing systems can be designed to step-down higher operating pressures.

Maximum surface speed: 2 m/s (394 fpm).

We hold a number of tools for Walkersele TBMS designs. However, as each tunnel boring machine is custom-built for a specific tunnelling project, we recommend that you contact us at concept design stage to discuss sealing requirements in detail.

Want to discuss your project, engineering or materials challenge expert to expert? Simply provide us with your contact details and a little information about the application you are working on, and one of our experts will contact you as soon as possible.