You are currently viewing the James Walker Global website.

You are currently viewing the James Walker Global website.

The customer, one of the largest global producers of gas-to-liquids products have been looking for the most reliable packing solution for their critical oxygen on/off valves in the gas separation process plant, part of a large refinery facility.

The customer, one of the largest global producers of gas-to-liquids products have been looking for the most reliable packing solution for their critical oxygen on/off valves in the gas separation process plant, part of a large refinery facility.

Oxygen service is a very critical and dangerous application where sealing solutions must have exceptional cleanliness levels to mitigate any risk of self-ignition when in contact with oxygen under high

temperature and pressure.

The customer, looking for the safest, fully controlled and most temperature resistant packing, has run an extensive validation programme reviewing all well known oxygen packing solutions available on the market.

The main criteria defined in the validation process were: suitability of packing in oxygen service with exceptional cleanliness levels confirmed by BAM Institute (BAM test report), packing oxidation rate in high temperature, supplier manufacturing capabilities - clean room, in-house batch testing capabilities as well as traceability.

Gate valves handling oxygen in the air separation unit.

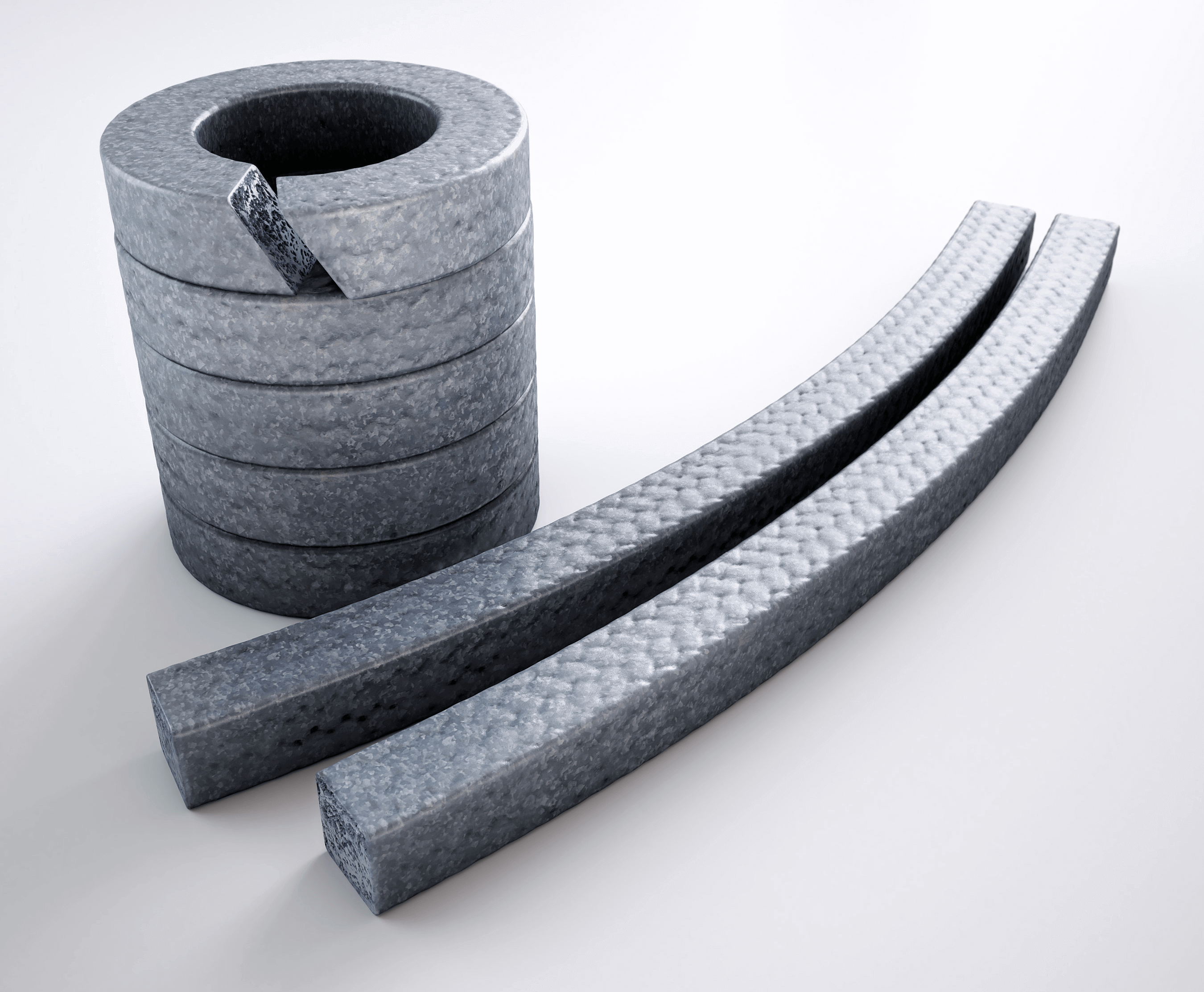

Alternative compression packing products designed for oxygen service.

Supagraf OX packing was recommended for exceptional levels of cleanliness. This product is manufactured and hermetically packaged in a state-of-the-art clean room facility with performance confirmed by outstanding BAM test results. The product has been qualified by BAM Institute in Germany for liquid and gaseous oxygen service. It is made using a very high quality grade of graphite with very low oxidation rates.

This provides long service life in high temperature applications and meets Shell MESC 85/204 specification as well as passing demanding ISO 15848-1 fugitive emission testing, one of the essential requirements from the Oil & Gas sector.

Following successful validation, Supagraf OX packing has been chosen and qualified by the customer as their preferred stem sealing solution.

Multiple cross sections in length form have been supplied and installed in valves with service life exceeding the requirement of 12 months.

This has led to a significant improvement in health and safety on-site, it has reduced downtime and ultimately improved the general air separation process plant efficiency.