You are currently viewing the James Walker Global website.

You are currently viewing the James Walker Global website.

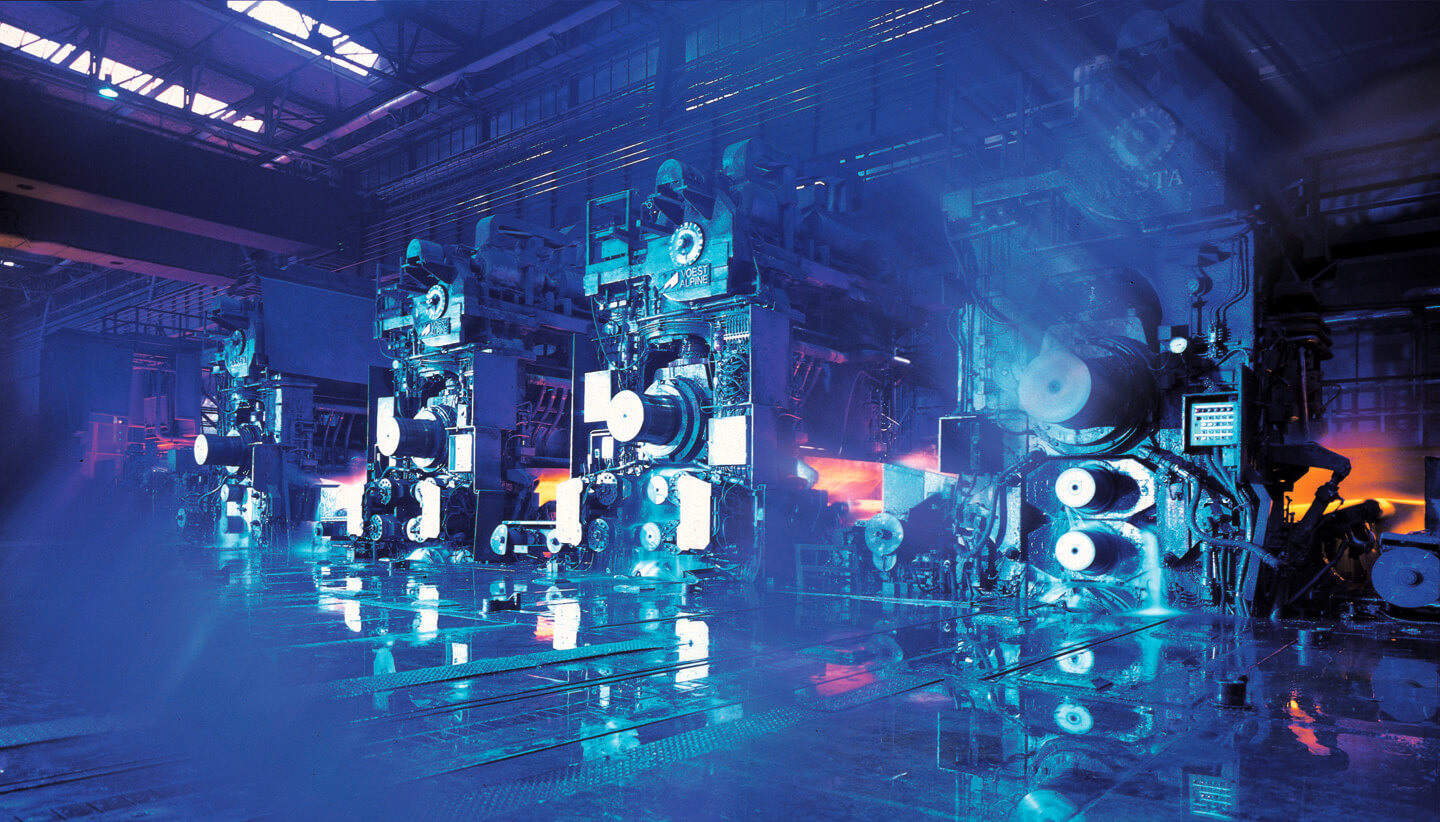

Due to difficult and confined access around steel mill rolling machinery the weight of standard metal thrust collars makes replacement or maintenance extremely difficult, time consuming and hazardous. Several collars have to be changed on a daily basis and the weight of the standard parts is too great for a single person lift. This impacts on the time it takes to change the rollers and often involves using heavy tools to assist. Our customer had given us the challenge to reduce the weight of these components and if possible make fitting and replacement a tool-free job.

Thrust collars on work, support and back-up rollers in a steel rolling mill.

Heavy, 30kg, metal thrust collars requiring heavy tooling and potentially lifting gear or more than one person to complete the changeout.

The thrust collar was redesigned and manufactured in Devlon T100 thermoplastic material. This reduced the weight of these items by over 20kg per unit making single operator handling a far easier task. As part of the redesign a latching system was included, allowing for the thrust collars to be removed and replaced without the need for tools.

The lightweight Devlon engineered thermoplastic thrust collars were installed and have been operating successfully. The new thrust collars are able to be fitted easily and safely and offer much improved handling.

The weight saving of over 20 kg per collar allows for a much faster changeout process and has dramatically reduced the health and safety concerns caused by the very heavy metal collars previously in use.

Want to discuss your project, engineering or materials challenge expert to expert? Simply provide us with your contact details and a little information about the application you are working on, and one of our experts will contact you as soon as possible.