You are currently viewing the James Walker Global website.

You are currently viewing the James Walker Global website.

Our customer, a large valve OEM, was looking to pass fugitive emission tests for their globe control valve according to ISO 15848-1 for wide temperature range from -196°C up to 400°C with required class C tightness and CC1 endurance.

Our customer, a large valve OEM, was looking to pass fugitive emission tests for their globe control valve according to ISO 15848-1 for wide temperature range from -196°C up to 400°C with required class C tightness and CC1 endurance.

These very stringent requirements for the valve came from the end user. Competitive solutions from the existing supplier did not give satisfactory results and the customer faced an issue of losing a big project for one of their main customers in the oil and gas industry.

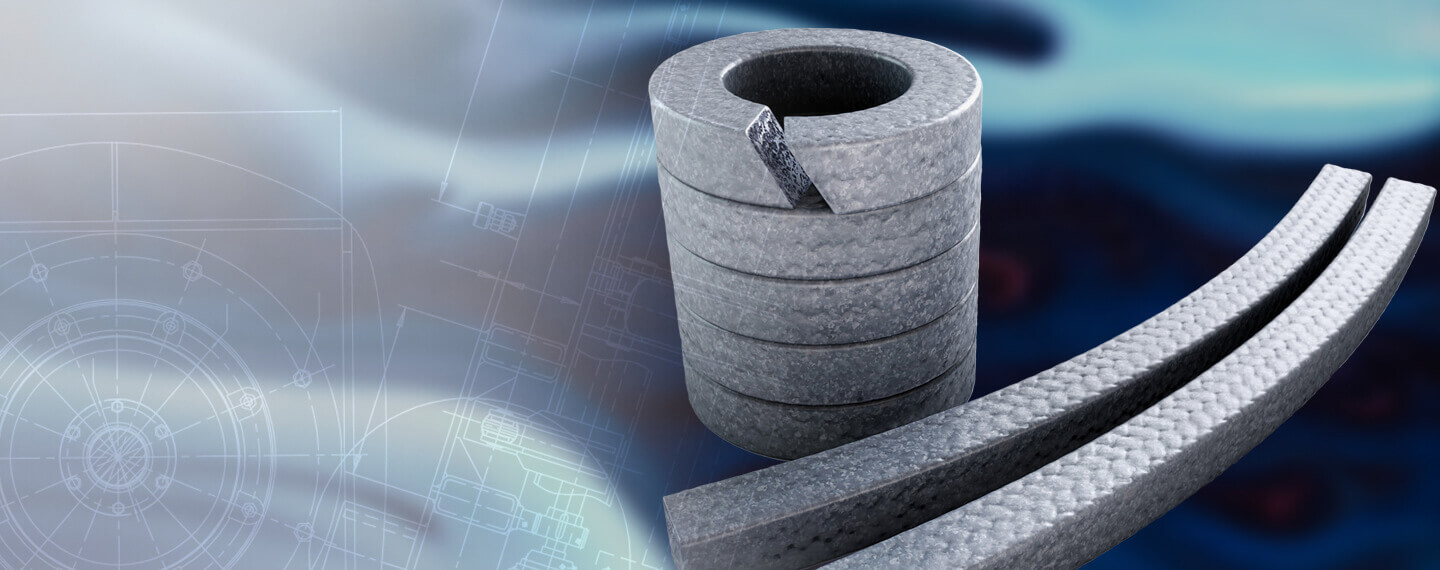

Control Globe Valve 4" Class 600

Competitor’s fugitive emissions graphite-based packing.

Supagraf Control 6 ring set (ID 25.4 mm OD 38.1 mm DP 38.1) was offered since this product has been specifically designed for control valve applications where fugitive emission performance is required.

Apart from its advanced lubrication package the product has non-metallic reinforcement that provides high pressure capabilities in dynamic applications, such as frequently operated control valves, as well as exceptional sealing performance.

The product has been certified to the highest industry standards including ISO 15848-1 and TA-Luft/VDI2440.

Despite very challenging test conditions (particularly related to very wide temperature range from -196°C up to 400°C and the required 20,000 mechanical cycles) the valve sealed with Supagraf Control passed the test - reaching class B tightness requirement and so exceeding the requirements (Class BH ISO 15848-1 CC1 -196°C to 0°C, Class BH ISO 15848-1 CC1 0°C to +400°C).

Want to discuss your project, engineering or materials challenge expert to expert? Simply provide us with your contact details and a little information about the application you are working on, and one of our experts will contact you as soon as possible.