You are currently viewing the James Walker Global website.

You are currently viewing the James Walker Global website.

Our customer was experiencing unacceptable leakage on their hot rolling mill back-up chocks, which was resulting in five seal change-outs per year.

Our customer was experiencing unacceptable leakage on their hot rolling mill back-up chocks, which was resulting in five seal change-outs per year.

Each change-out incurred significant labour and parts costs for the replacement of 90 seals, in addition to the loss of production whilst the plant was shut down for each unscheduled event.

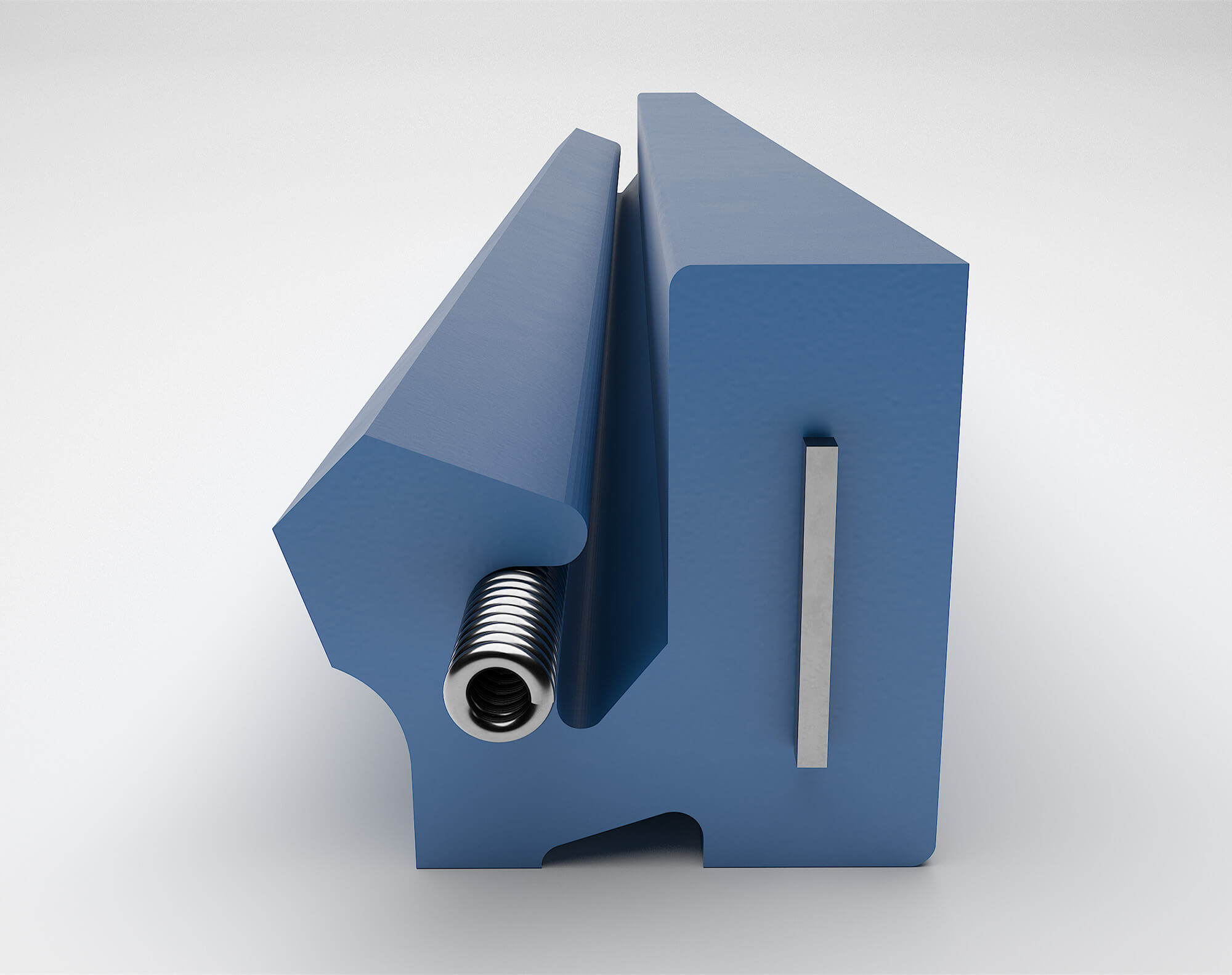

Hot rolling mill back-up chocks.

Worn equipment, a damaged housing and high levels of eccentricity were at the heart of the excessive oil leakage and the low cost seal option being used by the customer could not cope with these conditions.

The alternative solution offered by James Walker was a D7 Walkersele specifically designed for excessive eccentricity and a self-retaining fit.

The seal was manufactured in our Supaglide elastomer which also reduced the level of wear on both the shaft and seal, providing extended service life.

Despite the James Walker product being double the price of the low-cost seal the customer was originally using, the improvement in sealing performance and enhanced service life have provided a significant ongoing annual saving by focusing on Total Cost of Ownership rather than minimum component cost.

| Before | After | |

| Number of change-outs per year Labour hours per change-out Labour and lost production costs per hour |

5 4 £13,600 |

1 4 £13,600 |

| Number of seals per change-out Price of each seal |

90 £215 |

90 £438 |

| Annual wastage of oil through leakage | 5,000 litres | 0 litres |

| Annual cost of oil wastage Annual cost of seals Annual cost of labour and lost production |

£6,800 £96,750 £272,000 |

£0 £39,420 £54,400 |

| Total annual cost | £375,550 | £93,820 |

| Total annual saving | £281,730 |

Want to discuss your project, engineering or materials challenge expert to expert? Simply provide us with your contact details and a little information about the application you are working on, and one of our experts will contact you as soon as possible.