You are currently viewing the James Walker Global website.

You are currently viewing the James Walker Global website.

Why a seal with a long sealing life is highly advantageous in biopharmaceutical manufacturing.

Friday, July 19, 2024The drive from the biopharmaceutical industry is to increase efficiency and maximising output, and a seal with a long sealing life is highly advantageous as it greatly reduces downtime and maintenance costs.

Compression stress relaxation (CSR) is a measure of the sealing capacity of an elastomer. It gives the force (i.e. the sealing force) a rubber sample exerts on a solid sealing surface as a function of time

To understand the value of CSR testing it is helpful to understand how a rubber seal operates. In a static seal, the rubber seal is compressed between two parallel surfaces, as the material is elastomeric, the seal pushes back against the two surfaces, and this contact force prevents fluid flow past the seal, achieving a leak-free joint. Over time, the material will relax, and the sealing force will drop. In CSR testing, the sealing force is measured directly and can give an indication of the seal lifetime.

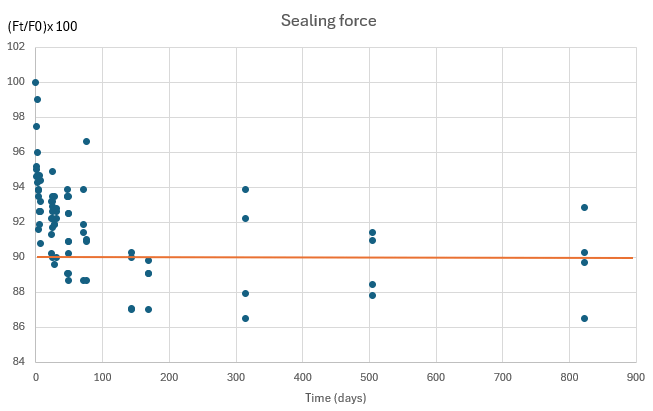

There are many sources of variation in CSR testing and great care must be exercised in sample preparation and testing. Consequently, the absolute forces measured may vary significantly, therefore to normalise the data the sealing force is calculated by dividing the measured value by the value at time zero and expressed as a percentage.

i.e. Fr = (Ft/F0) x 100,

where Fr is the retained sealing force at time t, Ft is the measured force at time t and F0 is the original measured force at time zero.

Of particular interest is our Elast-O-Pure® EP75B, a material specifically engineered for, and widely used in, biopharmaceutical applications.

Four samples of Elast-O-Pure® EP75B, in four different test cells, were tested at room temperature according to ASTM D-6147 but with a greatly extended test period, up to 822 days. The results are shown below:

There is some scatter in the data due to the sensitive nature of this test, however, as expected, there is an initial drop in the sealing force as the elastomer relaxes under load, most of which occurs in the first 14 days. After 30 – 40 days this stabilises at 90% and remains so for the duration of the test (2¼ years !).

This is a spectacular result; 90% of the original sealing force is retained even after 2¼ years.

This data demonstrates the long service sealing capability of Elast-O-Pure® EP75B, albeit at room temperature, and reinforces data from the biopharmaceutical industry that Elast-O-Pure® EP75B can extend elastomer change out periods, and shows the reason why it can.

Want to discuss your project, engineering or materials challenge expert to expert? Simply provide us with your contact details and a little information about the application you are working on, and one of our experts will contact you as soon as possible.