You are currently viewing the James Walker Global website.

You are currently viewing the James Walker Global website.

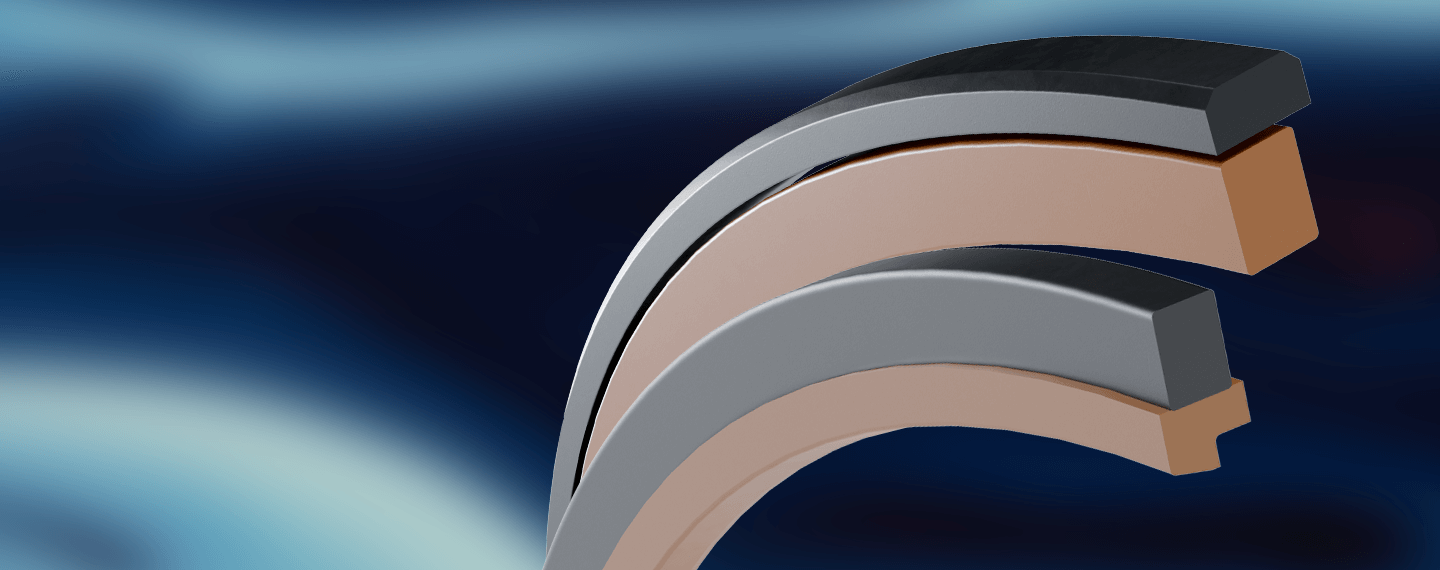

Specialised high‑performance composite seal for piston / rod sealing applications

Recommended for the most arduous applications in metallurgical plant

Fluolion® XT is a specialised high-performance material developed for arduous hydraulic seal applications in the metallurgical industry.

This well tried and tested low-friction material also has excellent abrasion resistance and has been used successfully over many years on composite seals for piston and rod applications.

In operation, the intimate face-to-face contact prevents the sleeve twisting or rocking in the housing. This provides stable fluid film conditions with consistently low friction values.

The sleeve controls leakage by recovering the maximum possible amount of residual fluid film deposited on the cylinder bore. Its chamfered leading edges assist with fluid film recovery, and also reduce the risk of seal damage through extrusion.

Fluolion XT improves composite seal performance to give high value-in-service and savings on cost of ownership, due to:

Fluolion XT is recommended for the most arduous applications in metallurgical plant, including:

Temperature range -25°C to +120°C (-13°F to +248°F) with NBR energiser

Temperature range -15°C to +200°C (+5°C to +392°C) with FKM energiser

Max speed 5.0 m/s

Maximum Pressure 40 MPa (400 bar)

Sealing element of specialised PTFE

Energising element of either nitrile (NBR) or Fluorocarbon (FKM) rubber

Fluolion XT is a specialist PTFE material and as such is resistant to the vast majority of chemicals. The energising element, made in either nitrile or fluorocarbon rubber, will be the main limiting factor in terms of media compatibility. Contact the James Walker technical team to discuss your specific requirements.

• Double and single acting piston designs, with strong or limited guidance systems

• A range of seal profiles to suit your most exacting applications