You are currently viewing the James Walker Global website.

You are currently viewing the James Walker Global website.

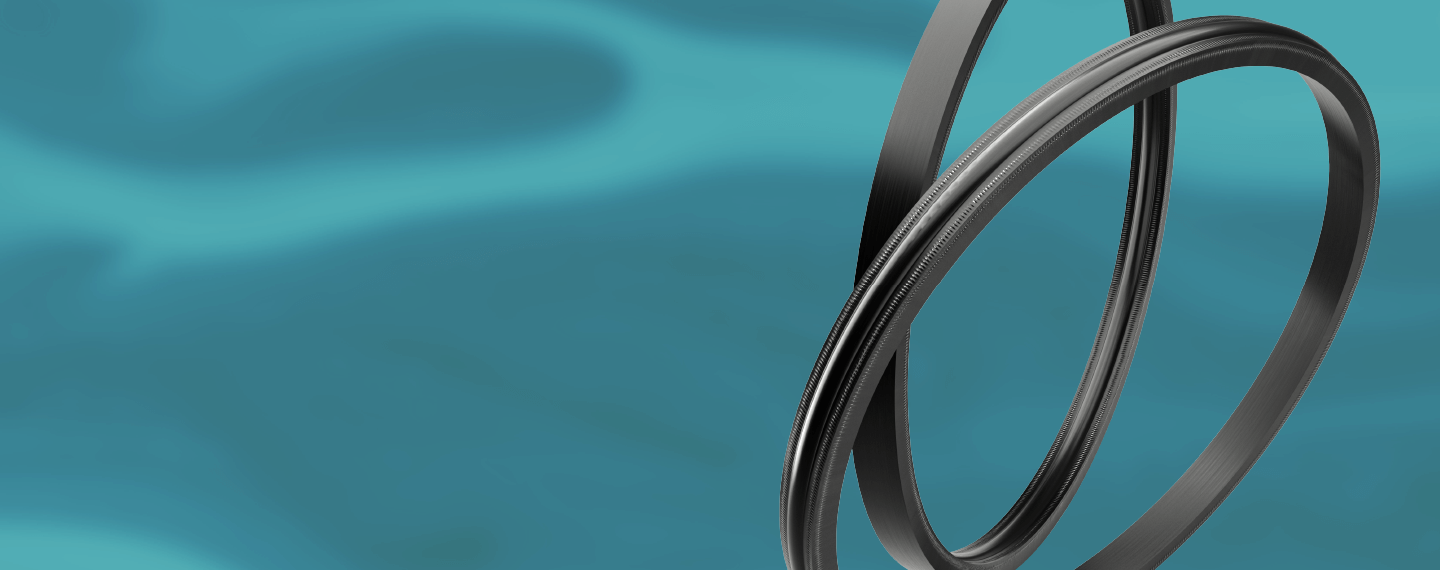

S‑Seals (also known as spring seals) specifically developed by James Walker for effective sealing on high pressure oilfield equipment with large extrusion clearances.

James Walker has developed Springsele, or S-Seals as they are also known, specifically to solve problems commonly experienced by the manufacturers and users of oilfield equipment. The seal is designed to be double acting, and will effectively seal applications that are subjected to:

Springsele is recommended for static duties and can operate at high pressures with large extrusion gaps.

Springseles have been tested by James Walker at pressures of up to 155 MPa (22500 psi). Customers have also reported that they have tested and validated Springseles in extreme pressures and temperatures in a wide range of challenging environments. Please contact us for advice on the most suitable size and material combination for your requirements.

Our specially developed S-Seals are available in a wide range of elastomer materials to suit demanding, high pressure applications. The available elastomers include:

FKMs: Vermilion One, Vermilion Two, Vermilion Three, Vermilion Four, FR25/90, and FR58/90

HNBRs: Vermilion Five, Vermilion Seven, Elast-O-Lion 985, and Elast-O-Lion 101

Other elastomers may be available. Please contact us for further advice.

These seals are used for many oil and gas duties, including:

Springsele can be:

Springsele is the preferred design for the majority of oil and gas applications (except where the duty is dynamic, in which case Teesele is recommended). This is due to ease of assembly of Springsele and its ability to work efficiently with large clearances. In addition, Springsele has gained acceptance as the standard for sealing casing receptacles in surface wellheads, where it is often used in conjunction with our FS seal.

*Note: The use of Springsele in applications where relative motion is experienced can result in wear or damage to metal components due to metal-to-metal contact between the spring and housing.

Want to discuss your project, engineering or materials challenge expert to expert? Simply provide us with your contact details and a little information about the application you are working on, and one of our experts will contact you as soon as possible.