You are currently viewing the James Walker Global website.

You are currently viewing the James Walker Global website.

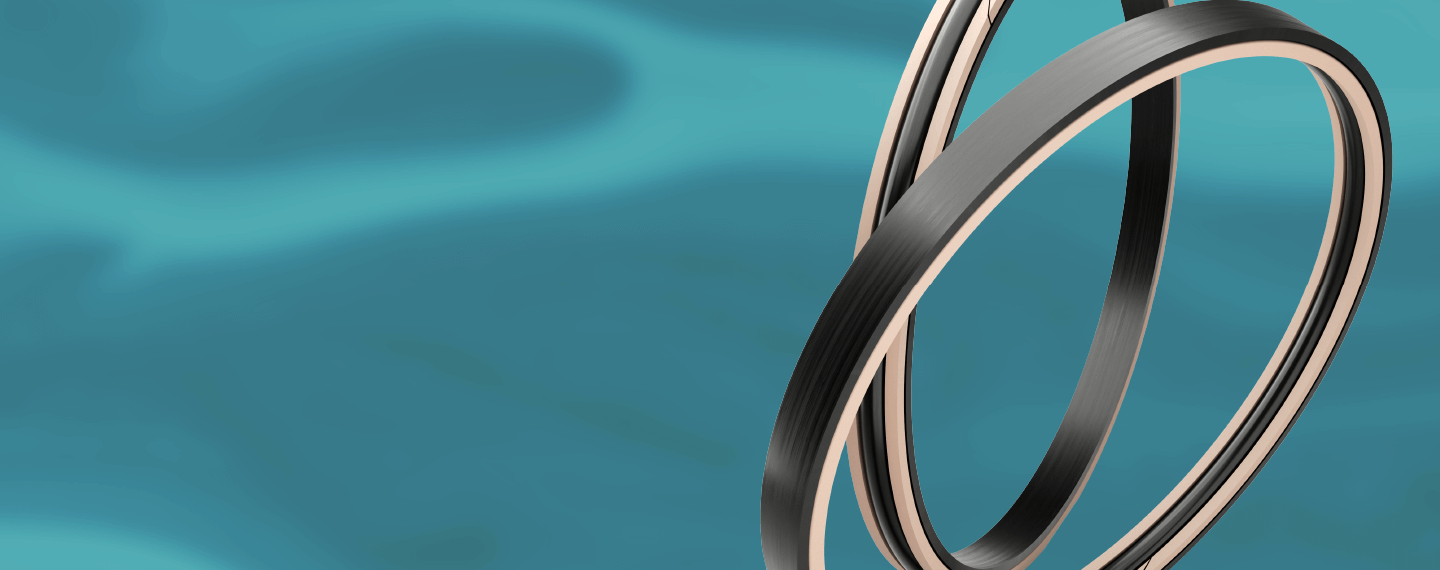

A multi‑piece, bi‑directional, dynamic seal developed for use in high‑pressure oil and gas applications

A Teesele (also known as Tee or T-seal) is a multi-piece, bi-directional seal developed by James Walker to meet the demanding requirements of the oil and gas industry in both static and dynamic applications.

Teesele has been designed for high pressure dynamic applications where the risk of extrusion damage is increased. Teesele is a multipiece seal suitable for linear dynamic applications, able to cater for larger clearance gaps at elevated pressures and temperatures, minimising the risk of failure in service. Utilising non-metallic anti-extrusion elements, the risk of damage to the sealing counter face is eliminated.

• Separate PEEK 450G anti-extrusion elements reduce the risk of extrusion damage at high pressures and temperatures.

• Teesele has been proven to operate with clearance gaps up to 1.5x the size of a conventional O-ring - reducing machining costs, and allowing for pressure dilation.

• The standard design geometry remains unchanged from the original product launched over 25 years ago and continues to be the preferred seal for a range of oil and gas applications.

• Independently validated by a wide range of oil and gas equipment manufacturers across a range of materials, pressures and sizes.

• Tested in-house by James Walker at pressures of up to 22,500 psi and 140°C.

• Teesele has been designed to work in conventional O-ring housing geometry as per BS ISO 3601 and SAE AS568, reducing the need to change equipment designs or re-machine housings.

Teesele is simple to install in both internal or external housing configurations. The use of split anti-extrusion rings allows them to be easily assembled into a blind recess accompanying the elastomeric component of the seal.

For further information, please refer to our Teesele fitting guide.

Our materials have been developed to offer the very best performance in the most extreme and challenging applications across the oil and gas sector including rapid gas decompression, extremes of temperature and chemical attack.

Teesele is available in a range of James Walker’s high-performance fluoroealstomer (FKM) and hydrogenated nitrile (HNBR) materials. Details of these can be found in the Oil & Gas Elastomer Materials Guide.

Selecting the right material can be an extremely complex task. If you’re unsure which grade to choose, would like clarification on the data available to support selection, or would like to discuss your application with an expert, please contact us.

Want to discuss your project, engineering or materials challenge expert to expert? Simply provide us with your contact details and a little information about the application you are working on, and one of our experts will contact you as soon as possible.